Polystyrene was injection molded a process that is slightly difference from "pressing." Polystyrene beads are heated into a liquid form and is then injected into a closed set of stampers in a press. Because there are no labels inside the stampers they need glued on after. But polystyrene records wear quickly and are very susceptible to cue burn. If you've ever bought one used you know what I'm talking about. They generally sound like crap. I have a couple on Mala Records I cant' bear to part with despite the noisiness.Tim Neely at Goldmine focused on the positive:

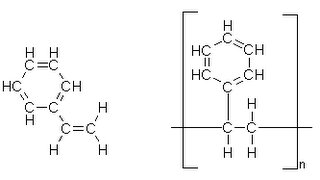

"Styrene records get a bad rap because they don’t tend to stand up to abuse as well as vinyl discs. That said, in near-mint condition, there is no audible difference between a vinyl and a styrene 45."The material can be air-injected to make styrofoam, or made into food-wrap, or dozens of other more appropriate items. But when making records there is only one advantage. It's cheaper. There are two reasons it's cheaper:

- The stampers last longer because they're not directly heated. Metal fatigue slowly destroys stampers in vinyl.

- The material can also be re-liquefied and reused .

The equipment for polystyrene and vinyl wasn't interchangeable. Polystyrene needs to be molded at much higher temperatures than vinyl for pressing. It's so much higher that they actually shrink while cooling. This is what causes that odd "orange rind" surface appearance. I have read that the Columbia Records pressing plant in Pittman, NJ was once a major producer of injection molded polystyrene pressings. I think that was the plant that made those dark-red polystyrene 45s from the mid 1970s. It is interesting to note that before the 70s all polystyrene records were black. I don't' know the significance of the color change.If you go looking for it let me warn you that it's subtle, you'll have to hold them up to a light to see it.

As you know, some funk and soul recordings were never re-released so the only pressings out there are the original polystyrene beasts. So when you see these rare discs up for auction or elsewhere consider that when you see the price. The condition will usually be pretty bad. These get more fragile with time, they break easily while cleaning, and the damn labels fall off. If you have some of these I can make two recommendations:

As you know, some funk and soul recordings were never re-released so the only pressings out there are the original polystyrene beasts. So when you see these rare discs up for auction or elsewhere consider that when you see the price. The condition will usually be pretty bad. These get more fragile with time, they break easily while cleaning, and the damn labels fall off. If you have some of these I can make two recommendations:

- Make a digital copy now and play that rip, not the record.

- If you insist on playing the record, use the lightest tracking weight possible, because the wear is only going to get worse.

No comments:

Post a Comment